In the realm of heavy machinery and industrial equipment, Twin Disc transmission systems stand as pillars of reliability and performance. However, like any mechanical component, Twin Disc systems may require maintenance and occasional replacement parts to ensure optimal functionality and longevity. Let’s delve into the intricate world of Twin Disc replacement parts and explore their significance in maintaining operational efficiency.

Understanding Twin Disc Transmission Systems

- Engineering Excellence: Twin Disc transmission systems are renowned for their robust design, precision engineering, and durability.

- Versatile Applications: From marine vessels to construction equipment, Twin Disc systems power a diverse range of machinery across various industries.

- Critical Components: Central to the functionality of Twin Disc systems are their intricate components, including clutches, gears, bearings, and seals.

The Importance of Replacement Parts

- Ensuring Continuity: Regular maintenance and timely replacement of worn or damaged parts are essential to prevent unexpected breakdowns and downtime.

- Preserving Performance: High-quality replacement parts uphold the performance standards of Twin Disc systems, optimizing efficiency and reliability.

- Cost-Effective Solution: Proactive replacement of parts mitigates the risk of extensive damage, reducing long-term repair costs and operational disruptions.

Common Twin Disc Replacement Parts

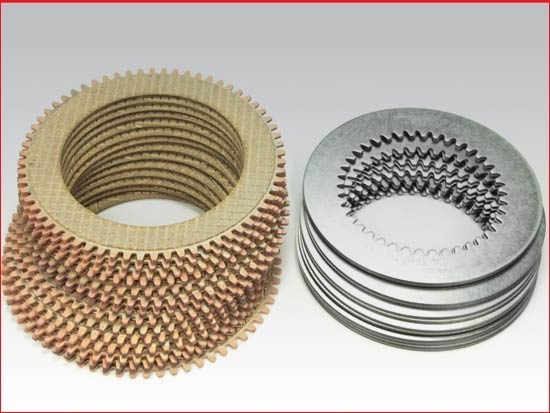

- Clutch Plates: Vital for transmitting power and facilitating smooth engagement and disengagement of the transmission.

- Bearings and Bushings: Support rotational motion and minimize friction, ensuring smooth operation and longevity.

- Seals and Gaskets: Seal critical components to prevent leakage of fluids and contaminants, preserving system integrity.

- Gears and Shafts: Transmit torque and rotational force, facilitating the transfer of power within the transmission system.

- Filters and Fluids: Maintain cleanliness and lubrication levels within the transmission, enhancing performance and longevity.

Sourcing Quality Replacement Parts

- Authorized Distributors: Procure replacement parts from authorized dealers or distributors to ensure authenticity and compatibility.

- OEM Specifications: Opt for parts manufactured to OEM specifications to guarantee fitment and performance.

- Quality Assurance: Verify the quality and reliability of replacement parts through certifications and industry standards.

- Expert Guidance: Seek advice from experienced technicians or service professionals to identify the most suitable replacement parts for your specific application.

The Role of Maintenance Practices

- Routine Inspections: Conduct regular inspections of Twin Disc systems to identify signs of wear or damage in replacement parts.

- Scheduled Maintenance: Adhere to recommended maintenance schedules and intervals to proactively address potential issues and replace worn components.

- Fluid Analysis: Perform fluid analysis to monitor the condition of lubricants and hydraulic fluids, identifying contamination or degradation that may necessitate replacement.

Conclusion

In the realm of heavy machinery and industrial equipment, the reliability and performance of Twin Disc transmission systems are paramount. The availability of high-quality replacement parts plays a crucial role in ensuring the seamless operation and longevity of these systems. By understanding the significance of replacement parts, sourcing quality components, and implementing effective maintenance practices, operators can uphold the efficiency and reliability of Twin Disc transmission systems for years to come.

From clutch plates to bearings and seals, Twin Disc replacement parts are the lifeline of transmission systems, ensuring smooth operation and longevity in the most demanding environments. Whether for marine, industrial, or off-highway applications, the availability of quality replacement parts is essential for maintaining operational efficiency and minimizing downtime.