⢠Cold weather affects manufacturing plants, reducing productivity and causing machinery to malfunction or break down.

⢠To protect against malfunctions and breakdowns, preventive maintenance services and heating solutions can be used.

⢠Employees may be more likely to take sick days due to illnesses. Implement flexible attendance policies.

⢠Supply chain and delivery delays may occur due to icy roads. Research suppliers in advance and have contingency plans.

⢠Preparation ensures production lines continue running smoothly even when temperatures drop.

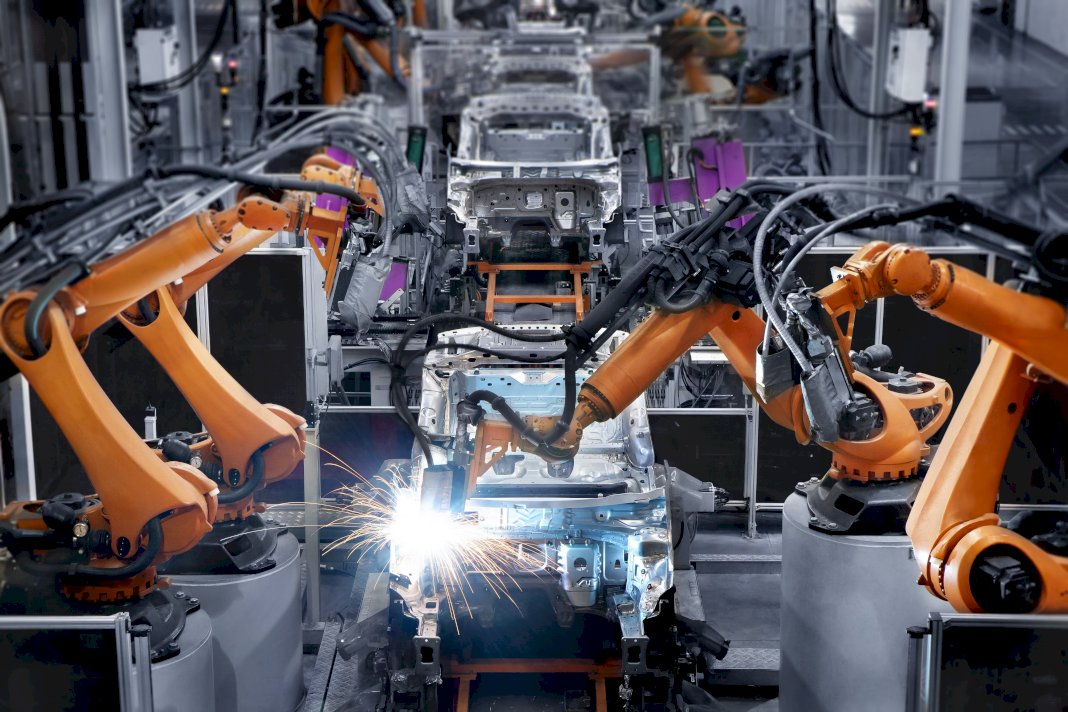

Winter can be a difficult time of year for manufacturing plants. Not only does cold weather take a toll on workers and equipment, but it also significantly affects productivity. If your business relies on production lines, you’ll want to be aware of the common issues plaguing factories in cold climates and have the plan to mitigate their effects. Here are ways the cold can negatively impact your business and what you can do about it:

Machinery Malfunctions and Breakdowns

When temperatures drop, factory machines tend to malfunction or break down more often than usual. This is because extreme temperatures make lubricants less effective, which causes parts of machines to wear out more quickly or cause components to freeze up completely. To combat this problem, try investing in preventive maintenance services like regular oil changes and inspection checks that address any potential problems with machinery before they become too severe.

You should also have the proper heating solutions for your machines, such as:

Insulation

Insulating pipes, tanks, and other large components of machines can help keep the oil in the system warmer and functioning correctly.

Heating blankets

These provide a cost-effective way to heat up motors or other parts that may be vulnerable to cold temperatures. Heating blankets can also be adapted to fit the size and shape of any machine.

Industrial Cartridge heaters

Industrial cartridge heaters are a highly efficient solution for heating metal parts, most often through insertion into drilled holes. Cartridge heaters are widely utilized in the heating process industry, offering precise and localized heating capabilities.

Radiant heaters

Radiant heaters provide an efficient and cost-effective way to keep entire machines warm during cold weather. Radiant heaters use infrared technology to heat the air surrounding machines quickly and help keep them functioning correctly.

These heating solutions can help keep your equipment running smoothly and reduce the amount of downtime due to malfunctioning parts.

Employee Absenteeism and Low Attendance

The colder temperatures mean employees are more likely to take sick days due to illnesses like colds and flu (not to mention snow days). This can create scheduling nightmares for managers who already have difficulty finding enough staff members.

To prepare for this issue, consider implementing flexible attendance policies that allow employees to take off work when they feel under the weather while still meeting production goals. Additionally, be sure your staff has access to protective clothing such as hats, gloves, scarves, and coats, so they stay warm while working outside in the elements.

Supply Chain and Delivery Delays

Cold weather can wreak havoc on supply chains due to delayed shipments caused by icy roads or frozen ports. As a result, businesses may end up having shortages of raw materials needed for production or finished products waiting longer than expected for delivery.

To avoid these types of delays, research suppliers ahead of time and partner with those who have reliable delivery schedules even during inclement weather conditions (e.g., warehouses located near shipping ports with easy access). Additionally, create contingency plans that outline how you will respond if there are delays in receiving materials or products due to poor road conditions or other unexpected factors associated with winter weather.

High Energy Costs

Due to the need for heating and other energy-intensive processes, factories tend to experience higher energy bills during winter months. To offset this, consider switching to renewable energy sources like solar or wind power, as well as exploring ways to reduce energy costs through increased efficiency. You should also make sure your energy management systems are up to date and working correctly, as these can monitor usage and alert you to any areas where there may be over-consumption.

As you can see, winter weather can potentially cause significant disruptions in manufacturing plants. To protect against machinery malfunctions and breakdowns, supply chain delays, absenteeism among employees, and high energy costs, it’s essential to start planning ahead now. From preventive maintenance services and heating solutions to flexible attendance policies and renewable energy sources – there are a variety of ways businesses can prepare for cold weather manufacturing challenges. These steps will help ensure that your factory continues running smoothly even when temperatures drop outside!